USD 9 - 9.5 / Meter

Brand:WEIYINGSI

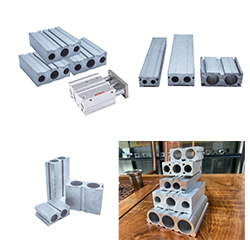

Model No:Double Rod Cylinder Tube

Transportation:Ocean,Land,Air,Express

Packaging:1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities

Supply Ability:100000Meters/month

A dual axis cylinder, also known as a double acting cylinder or double acting cylinder, is a pneumatic actuator that has two piston rods and two action surfaces, capable of linear motion in two directions. Unlike single acting cylinders (usually...

USD 9 - 9.5 / Meter

Brand:WEIYINGSI

Model No:Three-axis Cylinder Barrel

Transportation:Ocean,Land,Air,Express

Packaging:1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities

Supply Ability:100000Meters/month

A three-axis cylinder, also known as a double guide rod cylinder, is a special type of pneumatic actuator that has a piston shaft and two guide shafts. This design enables the three-axis cylinder to provide very stable linear motion during...

USD 9 - 9.5 / Meter

Brand:WEIYINGSI

Model No:TCN 16*2

Transportation:Ocean,Land,Air,Express

Packaging:1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities

Supply Ability:100000Meters/month

TCN/TCM Pneumatic Aluminum tube for three-axis cylinder barrel A three-axis pneumatic system typically refers to three independent linear motion axes used in an automation device or robotic arm. Each axis is usually driven by a pneumatic cylinder to...

USD 9 - 9.5 / Meter

Brand:WEIYINGSI

Model No:TN 16*2

Transportation:Ocean,Land,Air,Express

Packaging:1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities

Supply Ability:100000Meters/month

TN/TR/CXS DUAL ROD AIR CYLINDER ALUMINUM TUBE Short Description: The Aluminum Tube used for making Airtac standard TN TR and SMC standard CXSM Dual Rod Air Cylinder. Dual rod pneumatic cylinder have SMC standard CXSM, Airtac standard TN, Airtac...

USD 9 - 9.5 / Meter

Brand:WEIYINGSI

Model No:TN Series Double Rod Pneumatic Cylinder Barrel

Transportation:Ocean,Land,Air,Express

Packaging:1. Film anti wear protection 2. Optional cardboard packaging 3. Use export wooden boxes for large quantities

Supply Ability:100000Meters/month

AiTAC is a well-known manufacturer of pneumatic components, and its dual axis cylinders are widely used in automation equipment. They are mainly used in situations that require linear motion in two directions to save installation space and achieve...

◆ Operating speed: 50-500mm/s

A three-axis cylinder typically refers to the use of three independent linear cylinders in a system to achieve motion in three-dimensional space. In automation and robotics technology, such configurations can be used to achieve precise position control and object movement. Each cylinder is typically responsible for one axial movement (e.g. X, Y, Z).

Here are some key points about three-axis cylinders:

Structure:

Usually composed of three independent linear cylinders.

Each cylinder is installed in a mutually perpendicular direction, forming a three-dimensional coordinate system.

Application:

Part positioning on automated assembly lines.

Position adjustment of end effectors in industrial robots.

Accurate movement in material handling systems.

Sample processing in laboratory equipment.

working principle:

By compressing air, the piston is pushed to move inside the cylinder.

The extension and contraction of the piston rod drives the mechanical structure to move along a specified axis.

The combined motion of three axes can achieve complex spatial trajectories.

Control system:

PLC (Programmable Logic Controller) or specialized motion controller may be required to coordinate the actions of the three cylinders.

Sensors are used to provide feedback on position information to ensure precise control.

characteristic:

Compact structure, suitable for application environments with limited space.

Quick action, suitable for high-speed operation scenarios.

Maintenance is relatively simple because the main components are pneumatic.

Dual axis cylinder usually refers to a specially designed pneumatic actuator that can generate motion in two directions. This type of cylinder is typically used in applications that require linear motion on two axes simultaneously or separately. Here is some basic information about dual axis cylinders:

Basic concepts

Definition: A dual axis cylinder is a pneumatic component capable of producing linear motion on two axes simultaneously or separately.

Application: Widely used in automated production lines, material handling, precision positioning, and other situations that require multi axis control.

Structure and Type

Parallel dual axis cylinder: Two cylinders are arranged in parallel, and the piston rod can move synchronously or independently.

Coaxial dual axis cylinder: Two cylinders share a piston rod and control the movement of the two shafts through different air paths.

Other types: There are also specially designed dual axis cylinders, such as dual piston rod cylinders, which can install two piston rods on one cylinder block.

working principle

Compressed air drive: By using compressed air to push the piston inside the cylinder, it drives the piston rod or connecting piece to move along a predetermined axis.

Independent or synchronous control: Depending on the needs, the motion of each axis can be independently controlled, or two axes can be synchronized through specific design.

Control system

Electromagnetic valve: used to control the direction of airflow, thereby controlling the expansion and contraction of the cylinder.

Sensors: Displacement sensors or proximity switches can be installed to monitor the position of the piston and achieve precise control.

PLC or controller: It is usually necessary to coordinate the working sequence and speed of the cylinders through PLC or other controllers.

Application examples

Automated assembly: Dual axis cylinders can be used for positioning, clamping, or assembling parts.

Robot arm: As a part of the end effector of the robot, it achieves grasping and placing tasks.

Testing equipment: used in laboratories or quality control environments to simulate pressure or thrust testing.

characteristic

Compact: Compared to using two cylinders separately, dual axis cylinders have an advantage in space occupation.

Flexibility: Different travel lengths and installation methods can be customized according to application requirements.

Economy: Reduce installation space and costs while maintaining high performance.

FAQ

Important things you should know

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.